March 2, 2022

(press release)

–

Since January 2021, Kao Corporation and Kyoto University have been conducting verification testing of a Used Disposable Diaper Carbonization Recycling System in cooperation with Saijo City, Ehime Prefecture, Japan. Technology for converting used diapers into carbon material is expected to be established by 2023, with public implementation scheduled to begin in or after 2025. This is a report on current progress with the project. Overview Objectives The goal of achieving these two objectives is to contribute to reducing environmental impact by reducing CO2 emissions. Targets Establish technology for converting used disposable diapers to carbon material by 2023 Progress Development of carbonization equipment The newly developed carbonization equipment, and used disposable diapers being put into the device Carbonized used disposable diapers Verification of issues around use of the carbonization equipment at a childcare facility Future developments The carbonized used disposable diapers will be collected from the carbonization equipment installed at the childcare facility in Saijo City, and Kao and Kyoto University will carry out research into converting them into carbon materials; the goal is to establish this conversion technology by 2023. Saijo City will also consider building a resource recycling system. A review of infrastructure, including sites for installation of carbonization equipment and collection methods, will also continue in advance of the public implementation of a recycling system in 2025 and beyond. Initiatives for Kao's ESG Strategy, the Kirei Lifestyle Plan and plastic circularity in society Recognizing its responsibility as an enterprise that provides products which people use on a regular basis in their daily lives, Kao takes active steps to reduce the environmental footprint of its products throughout the entirety of the product lifecycle. In April 2019, Kao launched the Kirei Lifestyle Plan, its ESG (environmental, social and governance) strategy, which incorporates 19 key leadership actions. Kao's purpose is to create a Kirei life for all. The Japanese word 'kirei' describes something that is both clean and beautiful. For Kao, Kirei not only encapsulates appearance, but also attitude—to create beauty for oneself, other people, and for the world around us. The Kirei Lifestyle Plan aims to integrate ESG as the foundation of its management to accelerate business growth and create products and services of better value for consumers and society. *This news release is a translation of a Japanese-language news release dated February 24, 2022. About the Kirei Lifestyle Plan Over the past 130 years, Kao has worked to improve people's lives and help them realize more sustainable lifestyles—a Kirei Lifestyle. The Japanese word 'kirei' describes something that is clean, well-ordered and beautiful, all at the same time. The Kao Group established its ESG strategy, the Kirei Lifestyle Plan in April 2019, which is designed to deliver the vision of a gentler and more sustainable way of living. By 2030, Kao aims to empower at least 1 billion people, to enjoy more beautiful lives and have 100% of its products leave a full lifecycle environmental footprint that science says our natural world can safely absorb. https://www.kao.com/global/en/sustainability/ About Kao Kao creates high-value-added products that enrich the lives of consumers around the world. Through its portfolio of over 20 leading brands such as Attack, Bioré, Goldwell, Jergens, John Frieda, Kanebo, Laurier, Merries, and Molton Brown, Kao is part of the everyday lives of people in Asia, Oceania, North America, and Europe. Combined with its chemical division, which contributes to a wide range of industries, Kao generates about 1,420 billion yen in annual sales. Kao employs about 33,500 people worldwide and has 135 years of history in innovation. Please visit the Kao Group website for updated information. https://www.kao.com/global/en/ Media inquiries should be directed to: Corporate Strategy +81-3-3660-7043

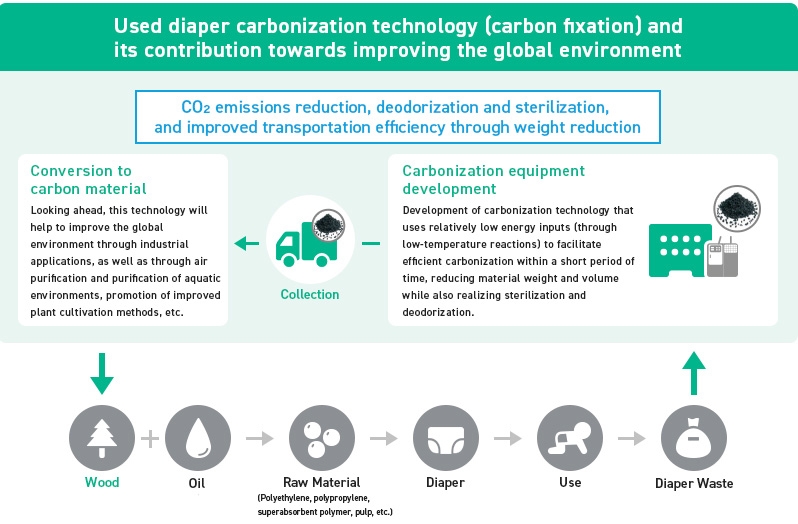

When used disposable diapers are incinerated, they generate CO2 emissions. However, when carbonization is performed, the carbon is fixed in carbon material, making it possible to reduce the amount of CO2 emitted, thereby reducing negative environmental impact.

Public implementation of the recycling system in or after 2025 (review of infrastructure, including sites for installation of carbonization equipment and methods for collecting used diapers)

By integrating ESG into the core of its company management, Kao will drive business growth and better serve consumers and society through its enhanced products and services. With this socially conscious ethos, Kao will create a Kirei life for all—providing care and enrichment for the life of all people and the planet.

Regarding the issue of plastic waste, which is a significant problem for society, in 2018, Kao announced its "Our Philosophy & Action on Plastic Packaging" declaration, and are abiding by the 4Rs: Reduce, Replace, Reuse, Recycle. We are substantially reducing the amount of plastic used in our packaging, by making them thinner, reusable, refillable, and reduced in volume, as well as improving our liquid concentration. We are also developing packaging that is easier to recycle. Plus, we will make efforts to switch away from fossil fuel-based plastics toward the use of sustainable materials.

In September 2019, Kao announced that it would be focusing on Innovation in Reduction and Innovation in Recycling, so as to help realize a society characterized by effective plastic resource circulation. In the area of Innovation in Recycling, we are collaborating with other companies and organizations on the horizontal recycling of plastic packaging. Initiatives for which we are undertaking verification testing include the recycling of film packaging made using multiple different materials, which in the past has been considered difficult to recycle, as well as recycling of mono-material film packaging (which is made using a single material), and of mono-material bottle containers. We are also conducting demonstration testing for many other projects, including recycling of items other than packaging, such as used diapers.

For more information please, click

Kao Corporation

* All content is copyrighted by Industry Intelligence, or the original respective author or source. You may not recirculate, redistrubte or publish the analysis and presentation included in the service without Industry Intelligence's prior written consent. Please review our terms of use.