TOKYO

,

April 4, 2023

(press release)

–

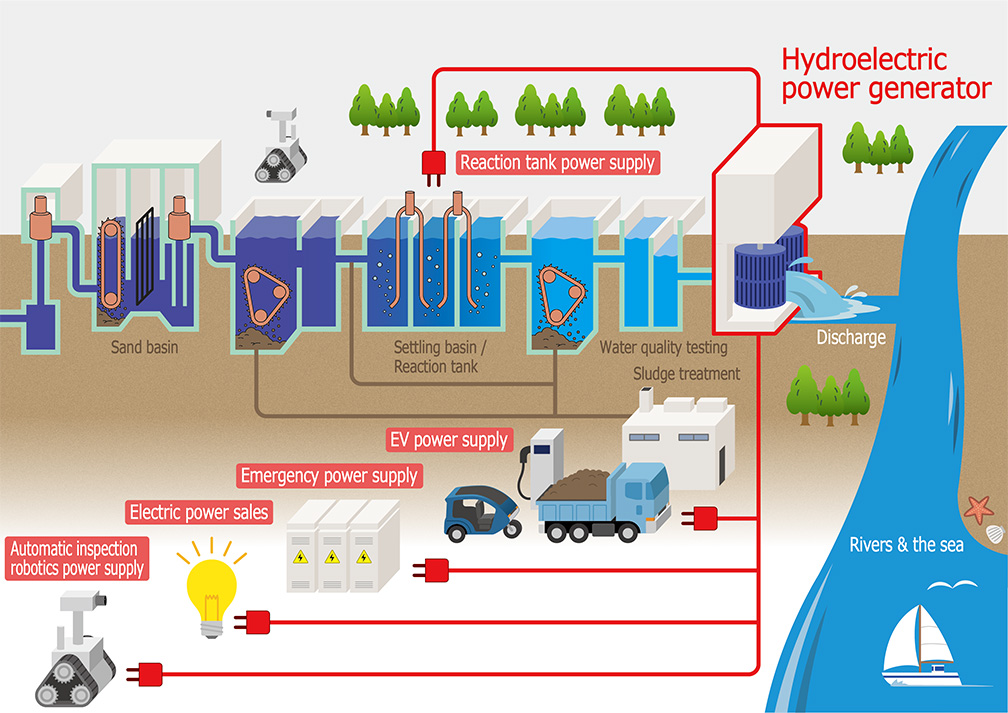

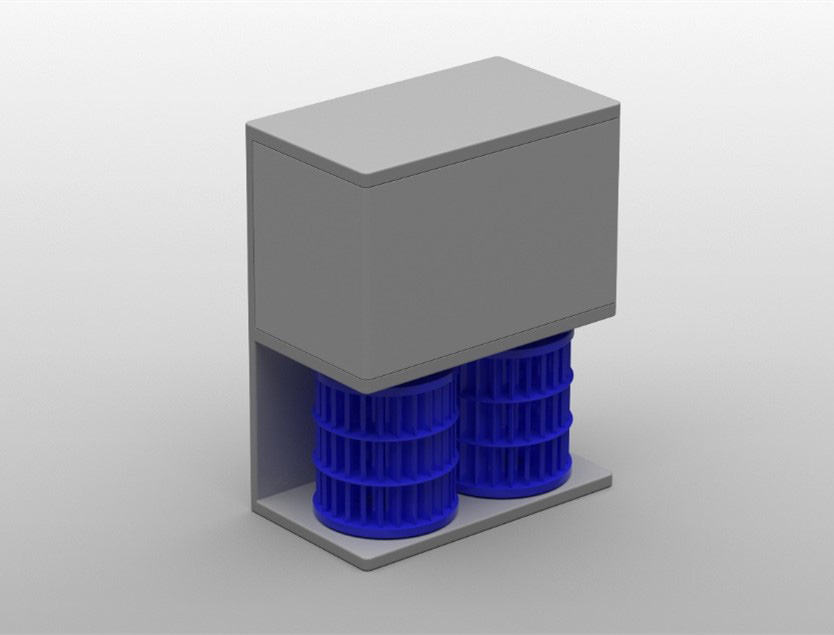

Ricoh Company, Ltd. (President and CEO: Akira Oyama) today announced that it has conducted a study on micro-hydroelectric power generation in sewage facilities utilizing 3D printers within the framework of applied research on sewerage led by Japan's Ministry of Land, Infrastructure, Transport and Tourism (MLIT), and submitted a completion report in March 2023. WEeeT-CAM, an in-house startup launched under Ricoh's new business creation initiative “TRIBUS,” participated in the study to examine the development of 3D-printed hydroelectric power generators. The study verified its usability at sewage treatment plant through industry-academia collaboration with Seabell Incorporated and Masashi YAMABE - Masahiro SETO Laboratory at Department of Mechanical Engineering, Kanazawa Institute of Technology. The study generated several kW of electricity using equipment with blades 25% lighter and main bodies 15% lighter than conventional metal hydroelectric power generation devices. The study also significantly shortened the production period from roughly one month to three days. The waterwheel part is made of resin for improved underwater durability. In the future, the electricity generated by these devices is expected to be used as emergency power supply at the disaster prevention centers within sewage treatment plants, and battery systems that provide power for mobility, as well as in crawler-type automatic inspection robots. In addition to installing micro-hydroelectric power generators at sewage treatment plants in Japan, we will continue to study the possibility of introducing the technology in Europe, the United States, and emerging economies. “Driving Sustainability for Our Future––Materializing Sustainability through Business”: Ricoh will continue to solve social issues through its business activities and provide value that is useful to society. Illustration of hydroelectric power generation equipment usage at a sewage treatment facility llustration of the micro-hydroelectric power generation device developed through this project Background Garage, sand, and dirt are allowed to settle out through the sewage treatment process. The sewage is then pumped into a tank to break down impurities using microorganisms. Keeping these microorganisms active requires a constant supply of oxygen into the water, which consumes approximately 75kWh*1, a considerable amount of electric power equivalent to roughly 110 billion yen*2 in electricity bills annually. So, there is a pressing need to reduce power consumption to conserve energy and lower costs. Some sewage treatment plants currently make use of micro-hydroelectric power generators, but conventional equipment poses the following issues: (1) low turbine efficiency and low output, (2) high purchase and installation costs of hydroelectric power generation equipment, (3) significant equipment heavily burdens the on-site personnel, and (4) the current micro-hydroelectric power generation equipment is challenging to use in environments that exacerbate rusting. In response to these issues, MLIT is currently engaged in technology demonstrations and applied research to realize green innovation in sewerage systems. In March 2022, a study commenced in the field of applied research for sewerage systems based on a proposal led by Ricoh. Details of the study Related News News release in PDF format | About Ricoh | Ricoh is empowering digital workplaces using innovative technologies and services that enable individuals to work smarter from anywhere. With cultivated knowledge and organizational capabilities nurtured over its 85-year history, Ricoh is a leading provider of digital services, information management, and print and imaging solutions designed to support digital transformation and optimize business performance. Headquartered in Tokyo, Ricoh Group has major operations throughout the world and its products and services now reach customers in approximately 200 countries and regions. In the financial year ended March 2022, Ricoh Group had worldwide sales of 1,758 billion yen (approx. 14.5 billion USD). For further information, please visit www.ricoh.com © 2023 RICOH COMPANY, LTD. All rights reserved. All referenced product names are the trademarks of their respective companies.

https://www.mlit.go.jp/mizukokudo/sewerage/content/001476160.pdf

* All content is copyrighted by Industry Intelligence, or the original respective author or source. You may not recirculate, redistrubte or publish the analysis and presentation included in the service without Industry Intelligence's prior written consent. Please review our terms of use.