January 3, 2024

(press release)

–

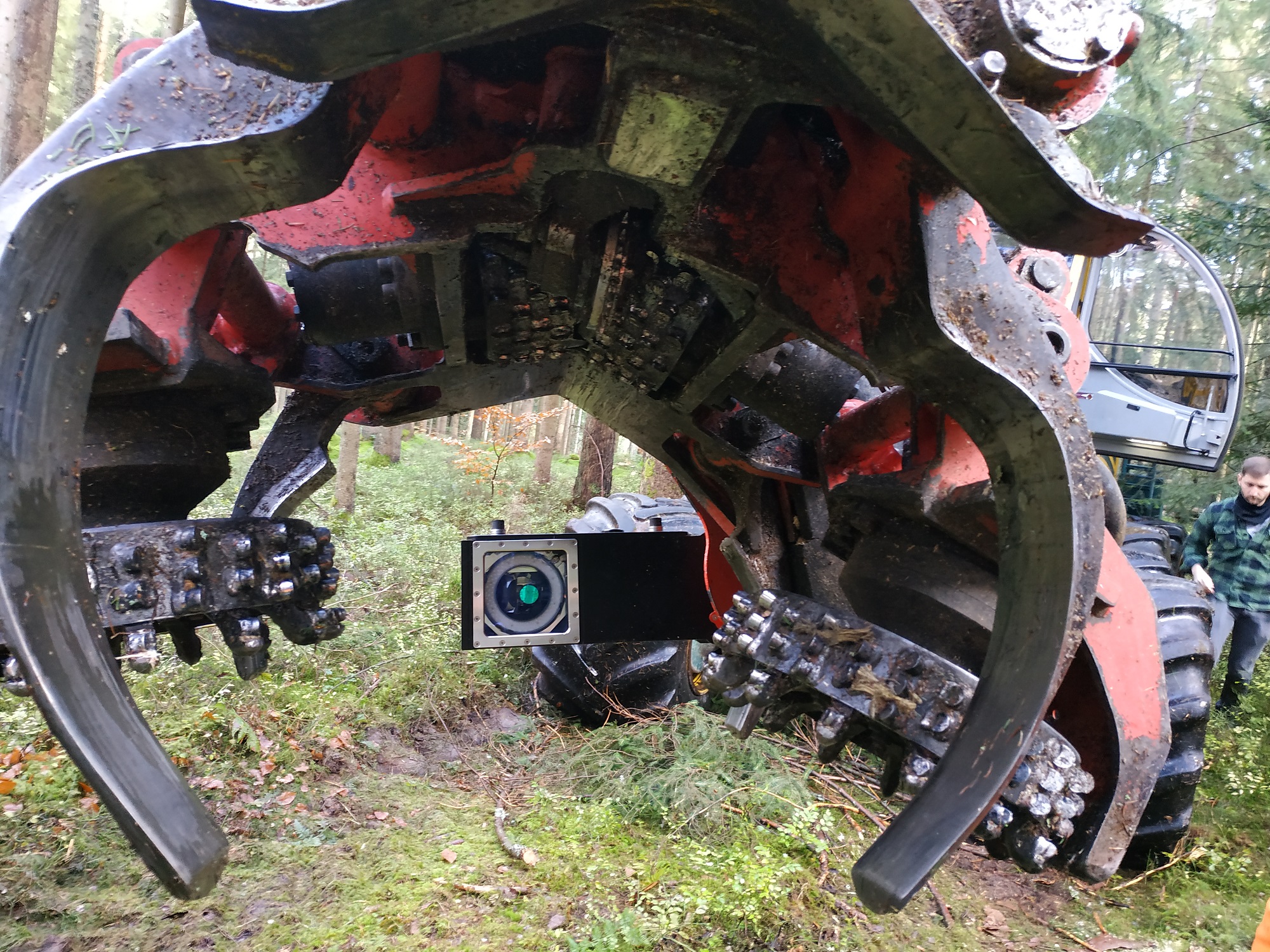

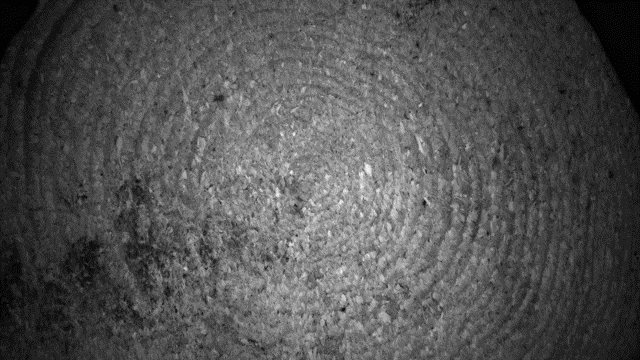

Until now, reliably tracing logs to their origin has been difficult to achieve. Researchers at Fraunhofer IPM and their partners have now shown that logs and trunk sections can be identified based on the structure of the cut surfaces. The recent research project developed a marker-free and tamper-proof method. The optical method allows up to 100 percent recognition – even under the rough environment conditions of the timber industry. Fälschungssicherer Herkunftsnachweis von der Ernte bis ins Sägewerk: Ein am Vollernter integriertes Kamerasystem nimmt die Schnittflächen von Baumstämmen auf und generiert daraus einen „Fingerprint-Code“. Mit einer erneuten Bildaufnahme kann der Baumstamm später anhand des Codes eindeutig identifiziert werden. Hochaufgelöst aufgenommen wird die spezifische Mikrostruktur von Sägeflächen erkennbar. Die Kamera-Aufnahmen werden auf eine simple Bitfolge reduziert – den Fingerprint-Code. Eine erneute Bildaufnahme desselben Oberflächenausschnitts ermöglicht die Identifikation des Stamms. Dass das Verfahren auch unter den rauen Bedingungen im Wald und Sägewerk funktioniert, konnten Forschende im Rahmen des Projekts DiGeBaSt zeigen. Timber is a valuable natural resource, and its role – particularly in the construction industry – is increasing. One objective of the EU timber regulation is to curb illegal timber trade. This is why the regulation requires wood-processing companies to ensure that timber can be traced to its origin along the entire supply chain. The numbering tags, RFID codes and simple color markings commonly used for identifying timber cannot ensure a reliable proof of origin because they are not tamper-proof. So far, alternative methods of marking logs and trunk sections have failed due to high costs and a lack of digitalization. Tamper-proof identification: Cut surfaces as fingerprints Fraunhofer IPM has been collaborating closely with the Forest Research Institute Baden-Württemberg (FVA) to develop a camera-based tracing method. The research project for the identification of logs and trunk sections has recently been concluded. The Track & Trace Fingerprint method uses the unique structures on cut surfaces like a fingerprint, meaning that no timber marking is required. High-resolution camera images of the cut surfaces are translated into a simple bit sequence, the fingerprint code. This code is matched with a unique ID and stored in a Cloud database. Tracking can thus be achieved by comparing new images of the same area with the corresponding bit sequence. This allows the tamper-proof identification of individual logs and trunk sections, even if the timber is mixed up during harvest and processing. Three different camera systems have been developed for wood processing applications, each to suit specific lighting conditions: a system that is integrated in a forest harvester, a system for use in a sawmill and a hand-held system. There are two reasons why the creation of fingerprint codes generates a vast amount of data: first, the specific structure of the cut surface with knots, growth rings and rough surfaces, and second, the forest environment, which makes the reproduction of log positions impossible. This is why the images are pre-selected in a two-step process using a convolutional neural network (CNN). High recognition rate In a field study, the researchers could show that the fingerprint method is reliable, even in the rough environmental conditions in the forest and the sawmill. A total of 65 cut surfaces were recorded on the forest harvester, at the timber collection point and at the sawmill. The registered sections were then identified at the collection point and at the sawmill by new images being taken at each location respectively. The recognition rate between the forest harvester and the timber collection point was 98.5 percent, in other words the system failed to recognize only a single log. Between the forest harvester and the sawmill, and between the timber collection point and the sawmill, the recognition rate was 100 percent. In the future, the researchers will be working on making the method suitable for other types of wood and for applications along the entire timber processing chain.  © Christoph Eberz / Fraunhofer IPM

© Christoph Eberz / Fraunhofer IPM © Christoph Eberz / Fraunhofer IPM

© Christoph Eberz / Fraunhofer IPM

* All content is copyrighted by Industry Intelligence, or the original respective author or source. You may not recirculate, redistrubte or publish the analysis and presentation included in the service without Industry Intelligence's prior written consent. Please review our terms of use.