September 7, 2023

(press release)

–

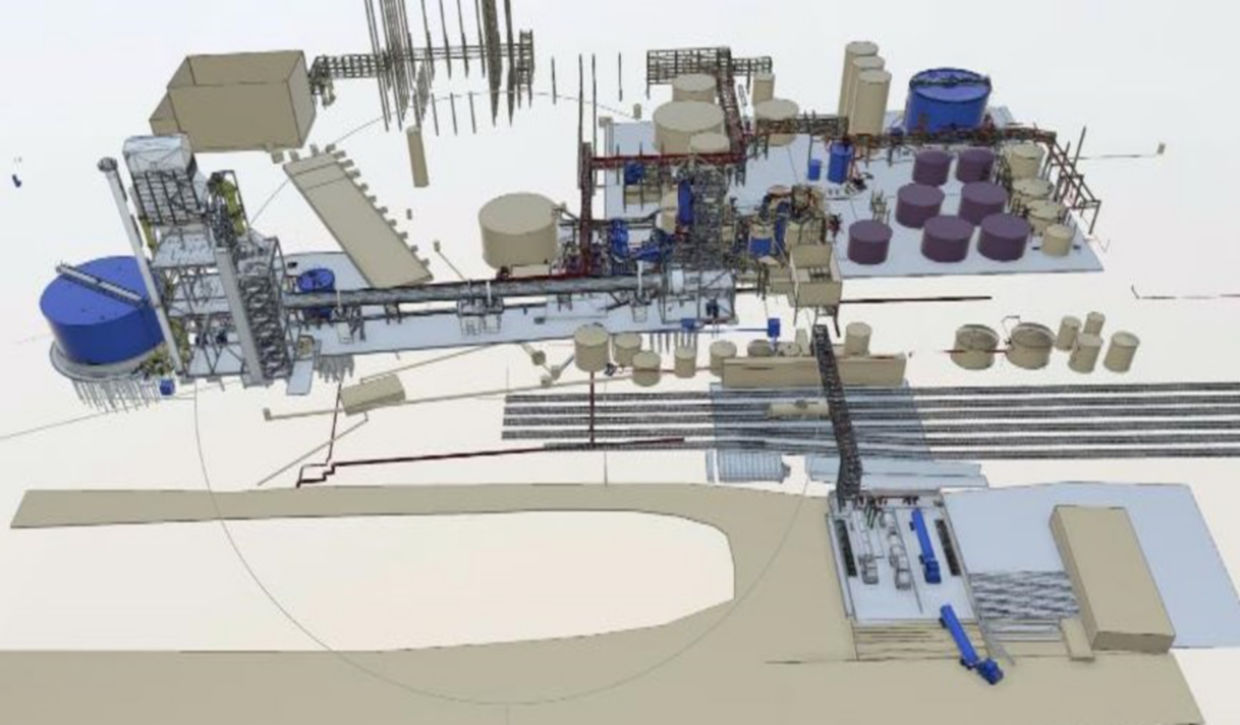

Big changes are happening in Brewton. The $160 million capital investment project into Georgia-Pacific’s Brewton containerboard mill is steadily progressing, allowing its operations to reach the next level. Some key components of the project are replacing outdated lime kilns, a new green liquor clarifier, a stabilization tank, a new truck unloading area, and a new white liquor clarifier. White liquor is a clear colorless liquid used in the kraft pulping process - pivotal in breaking down wood chips and fibers. The mixture helps remove impurities from the wood, creating a pulp that can be further processed into paper. The white liquor clarifier is responsible for clarifying and purifying the white liquor by removing solid impurities. This ensures efficient pulping, chemical recovery, and environmental compliance in the production of pulp and paper. “The Brewton team is excited about this project which is expected to be finished in late 2024. It will further GP's competitive advantage in the industry, stabilize our liquor processing systems, and reduce chemical and energy usage and maintenance expenses,” said Jerry Clark, Brewton’s vice president, and general manager. “Above all, it will enhance the safety of our 400-plus employees, which is our top priority.” The project aligns with Georgia-Pacific’s stewardship efforts to reduce the mill’s environmental footprint by minimizing wastewater, air emissions, and residuals going to the landfill by 45%. “For Brewton, this project goes beyond industry advancements. It’s about being the best employer; it’s about being the best community partner we can be. It’s those commitments we hold near and dear.” The new green liquor clarifier (GLC) is 75’ in diameter and 50’ tall and more than doubles Brewton’s current green liquor storage capacity. It’s used to separate the impurities, such as wood chips, bark, and other organic materials from the green liquor, which is then recycled back into the pulp cooking process. This helps to improve the efficiency of the process and reduce waste. The new truck loading/unloading area is already operational – a significant safety improvement to the previous location. A rendering of the completed project. Tags environmental stewardship governance Read Next%20(65%20x%2042%20cm)-1:Medium)

* All content is copyrighted by Industry Intelligence, or the original respective author or source. You may not recirculate, redistrubte or publish the analysis and presentation included in the service without Industry Intelligence's prior written consent. Please review our terms of use.