April 12, 2024

(press release)

–

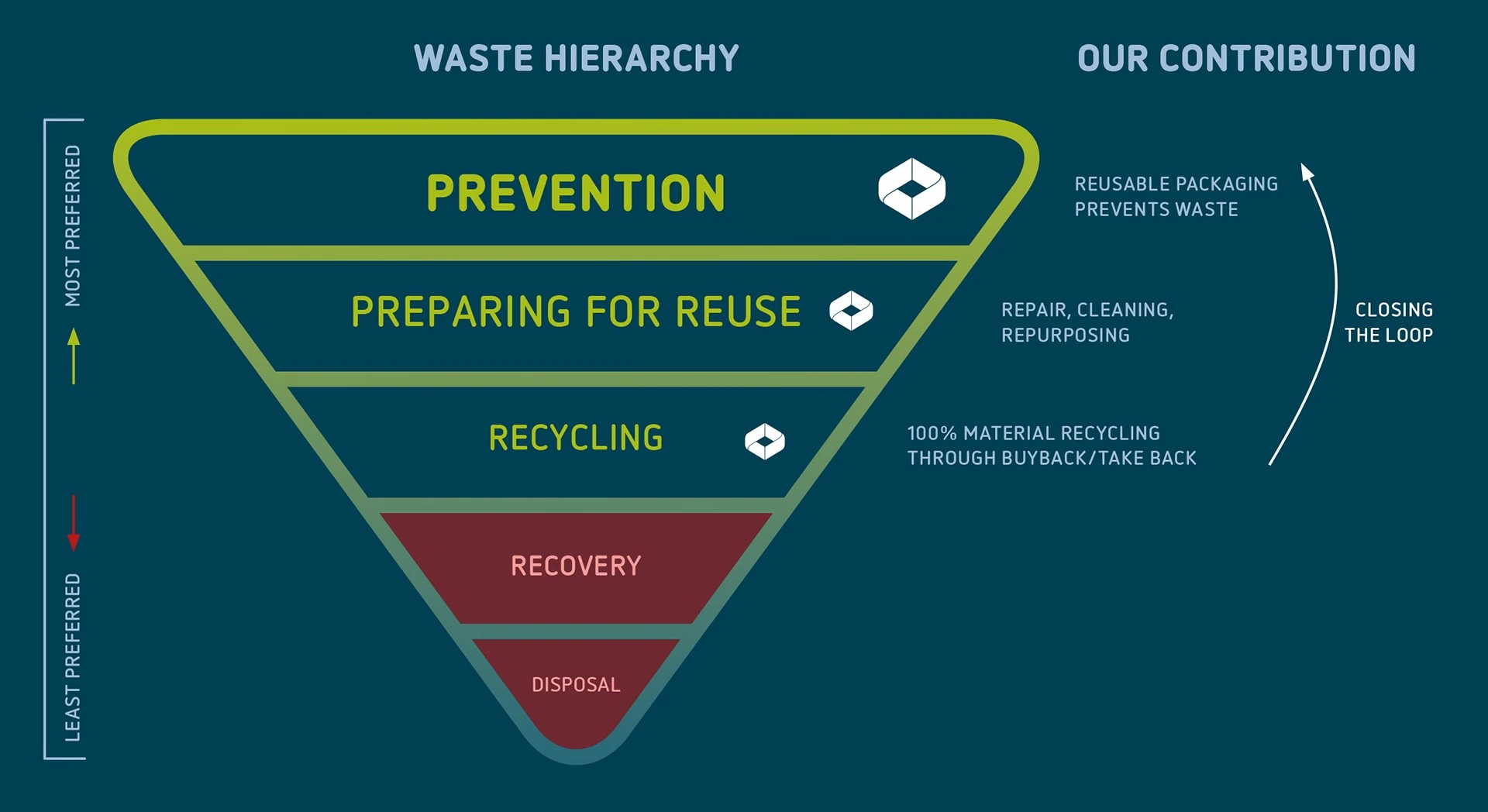

In a world where the traditional 'take, make, dump' approach prevails, it's imperative to pivot towards a more sustainable future. That’s why Schoeller Allibert is leading the way towards a circular economy, where products and materials are re-used instead of thrown out. Embracing this vision requires a long, hard look at our conventional practices, recognizing that not all waste is created equal. In fact, there is a waste hierarchy. If you’re concerned about the future welfare of the Earth and its inhabitants, the following statistic will be of interest: each year, we consumer about 100 billion tons of our planet’s natural resources, and each year, only 8.6% of that total is re-used. Linear vs. circular It's evident that our current linear trajectory is unsustainable in the long term, we risk depleting our precious resources, leading to rising costs and heightened pressure on supply chains and the economy at large. However, by embracing sustainable practices, we can reverse this trend. Transitioning to a circular economy not only conserves resources but also fosters resilience within supply chains, ultimately benefiting both businesses and the environment. As the symbol of the circle suggests, this model aims to keep resources in continuous circulation. This maximizes the utilization of resources, and reduces waste to an absolute (and ideally non-existent) minimum. Obvious and other advantages Maximum utilization, minimum waste: this is the circular economy’s main goal and most obvious advantage. But there are more. Circularity is a protection strategy against the inherent vulnerability of our global supply chains. In recent years, globalization has come under pressure for such diverse reasons as the Covid-19 pandemic, the Russia-Ukraine war, and disrupted trade routes. Each of these, and all of these combined, have had an effect on the availability of resources, which typically have to be shipped quite a distance from the places where they are sourced or manufactured, to where they are actually used. The circular economy can also be a bulwark against price increases and volatility. Prices of raw materials are not just subject to geopolitical events. Because of the laws of supply and demand, and for a myriad of other complex reasons, prices can suddenly shoot up, as they have done in recent years for copper (+70% since 2020) and lumber (more than doubled since 2020, with huge price spikes in between), for example. The latter was obviously instrumental in the recent skyrocketing prices for wooden pallets. But perhaps most importantly, the circular model goes beyond recycling, which is crucial, but not as good a solution as actually preventing waste. Of course, recycling is an important strategy and a valuable contributor to the circular economy. We at Schoeller Allibert pride ourselves on recycling marine plastic waste into new plastic crates - an excellent example of how recycling can contribute to circularity. But recycling implies the re-use of a product or material that is no longer functional, which, in other words, has become waste. There is, however a strategy that is superior to waste recycling, and that is waste prevention. We at Schoeller Allibert have a good example of this principle: our returnable transport packaging (RTP) - available to[HN1] rent or buy. Because they can be used again and again, our RTPs prevent the production (and subsequent waste) of single-use packaging. Our RTPs can be used hundreds of times over a multi-year lifecycle. And at the end of their useful life, they get recycled into new RTPs. Hence, in the case of RTPs, waste prevention and recycling are mutually reinforcing strategies. And not only that, at Schoeller Allibert, we also have successfully up-cycled plastic waste materials into high-quality containers and crates. The waste pyramid A good way to understand the intricacies of waste management (including recycling and prevention) is to picture an inverted pyramid, with five layers (see illustration). Each higher layer represents a more desirable outcome. At the very bottom is disposal: the material will not be re-used, and it ends up at a landfill. This is the worst outcome and unfortunately still happening in many places. One layer up is recovery: the material will not be re-used but via various means – anaerobic digestion, incineration, gasification or pyrolysis – energy is recovered from the waste, as fuel, heat or power. And then there’s recycling: turning used materials and waste into a new substance or products. This reduces the amount of new raw materials needed. Almost at the top, we have preparing for re-use: checking, cleaning, repairing, or refurbishing whole items or spare parts, so a product or material can be used again before it becomes waste. These four layers can all be considered waste management. The top layer is different: This is waste prevention. As is the case in medicine, prevention is the best cure. It’s at this level that our RTPs operate: the fact that the packaging is re-used over and over again, prevents the generation of (single-use) packaging waste. Schoeller Allibert goes circular Schoeller Allibert is a global leader in packaging solutions made from plastic. That makes our products not just hygienic and durable, but also ecological. But how can plastic be good for the environment? This may sound counter-intuitive, but the point is crucial. If you want to reduce the CO2 footprint and improve the sustainability of your logistics chain, the solution is not to replace one-way plastic with cardboard or wood, which have very limited reusability. The best solution is reusable plastic. Not only is it more efficient, flexible and sustainable, but it’s also better value for money. And as mentioned, our RTPs aren’t just reusable, at the end of their lifecycle they’re also recyclable into new RTPs, creating a 100% sustainable packaging cycle. Moreover, we are constantly innovating. In our extended test centre in Hardenberg (Netherlands), we’re always developing new materials to re-use. It all contributes to our closed-loop approach, which is part and parcel of our journey towards a fully circular economy. On the one hand, this benefits the planet, by keeping our finite resources in circulation and reducing the environmental impact of both sourcing new resources, and disposing of waste. And on the other hand, the circularity also benefits our customers, by reducing their packaging cost and carbon footprint. Why circular is the future The circular economy is not just a nice-to-have, something that ticks one of your company’s CSR boxes. It’s a must-have, and not just because it helps everyone fight the climate emergency and the degradation of our environment. But it’s also a want-to-have, because the benefits are not just reputational and ecological, but also economic. Circularity helps your company avoid the fragility of global supply chains, the volatility of raw material market prices, the cost of disposing of waste, and the price of continuously buying disposable packaging. For all those reasons combined, circularity is the future. And we at Schoeller Allibert are proud to play a part in our journey from the linear to the circular economy. To learn more about how you can contribute to – and benefit from – our circular products, get in touch! And be on the lookout for our Sustainability report of 2023. ©2023 All Rights Reserved by Schoeller Allibert. Part of the Brookfield group.

* All content is copyrighted by Industry Intelligence, or the original respective author or source. You may not recirculate, redistrubte or publish the analysis and presentation included in the service without Industry Intelligence's prior written consent. Please review our terms of use.