June 22, 2023

(press release)

–

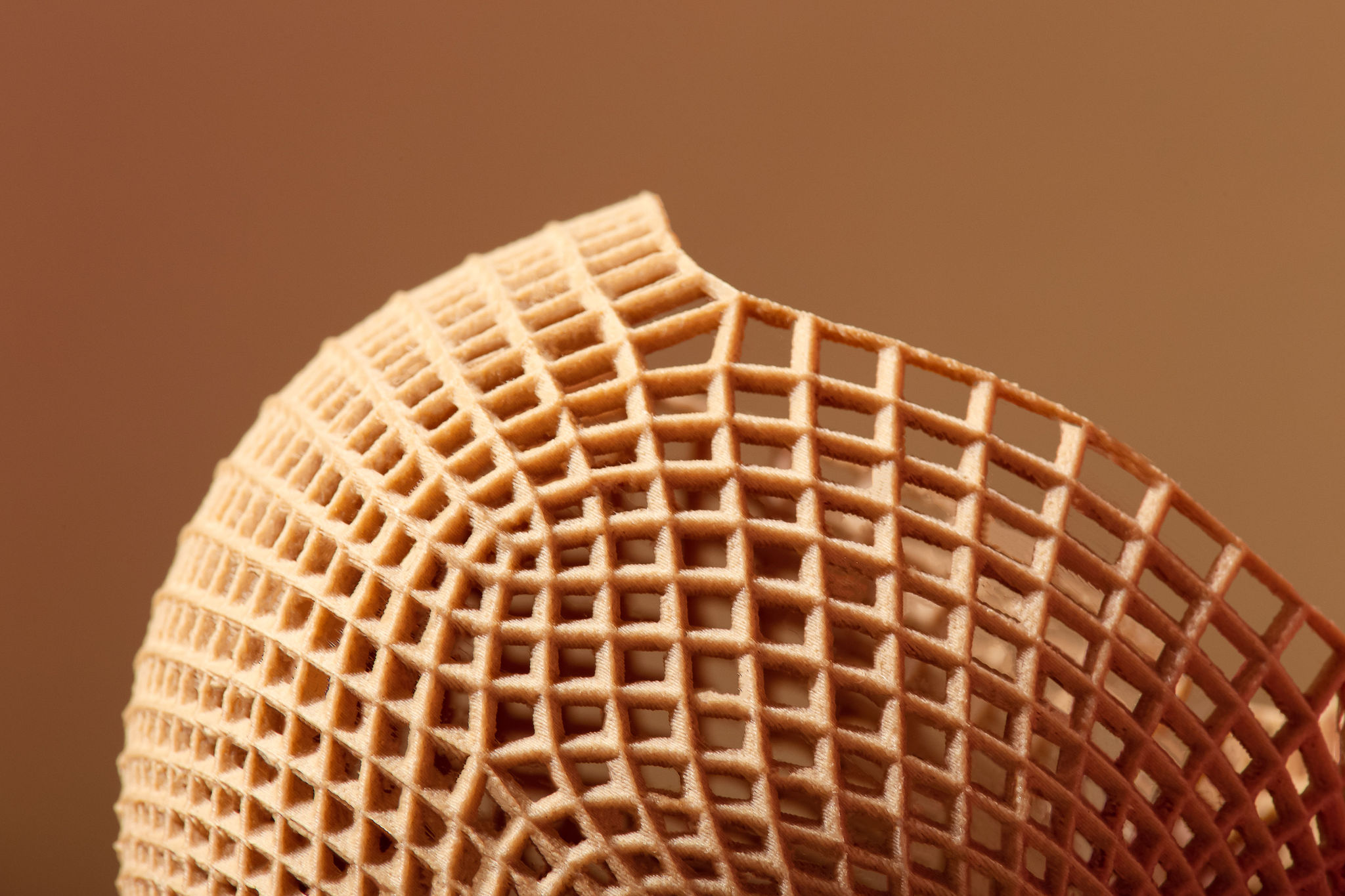

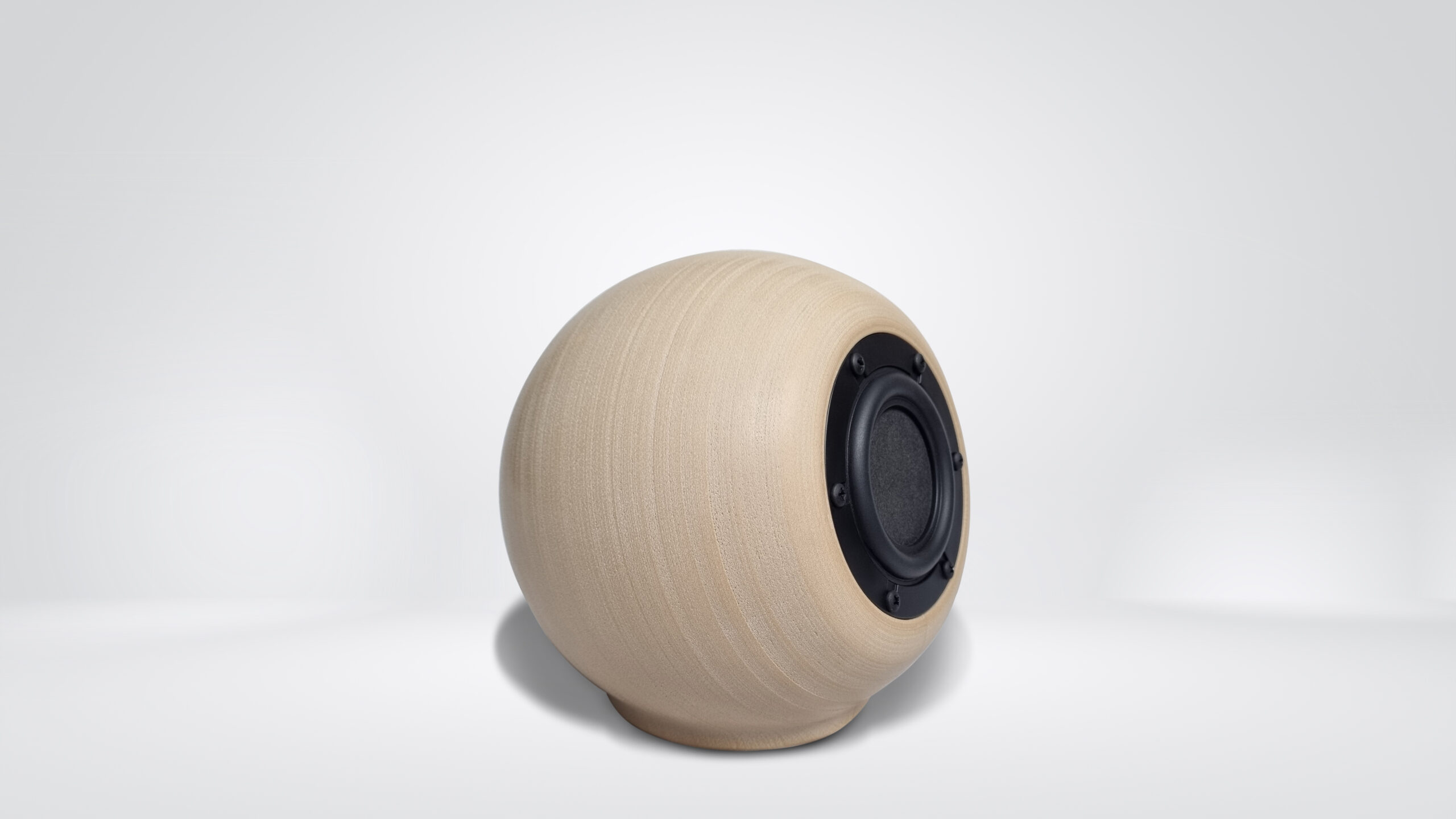

The potential of 3D printing is being unleashed, with an increasing array of applications across various fields and materials. The ecological credentials of 3D printing are one of the method’s many benefits. 3D printing with Sulapac takes the concept of environmentally friendly manufacturing even a step further. 3D printing is becoming increasingly popular among manufacturers, and no wonder; there are some undeniable benefits to this manufacturing technology. 3D printing is flexible in design: it can be used to create exactly the shapes you want. It’s perfect for pieces that are not needed in large quantities but have challenging shapes. Depending on the design and complexity, 3D printing can produce objects in a matter of hours, which is much faster than casting or machining. As this technology reduces material waste, the process is inherently more environmentally friendly. The environmental benefits are further extended by replacing the material used with an eco-friendly one. Meet Flow 1.7 – unlike any other material for 3D printing An excellent example of an eco-friendly material suitable for 3D printing is our wood-based Sulapac Flow 1.7 biocomposite. Sulapac Flow 1.7 was originally developed for the extrusion of straws, but we found, as a result of comprehensive tests conducted by various parties, that it’s highly suitable for 3D printing, too. In fact, this applies to some of our other materials as well. The suitability of Sulapac Luxe and Sulapac Universal Heat material families for 3D printing is currently under investigation. As with all Sulapac materials, Sulapac Flow 1.7 is bio-based and certified industrially compostable. After use, the material can be chemically recycled back to its building blocks and used to create new products. There are no persistent microplastic emissions at any stage of the life cycle. If the material would accidentally end up in nature, it doesn’t harm the ecosystem. There are other bio-based materials suitable for 3D printing on the market too, but Sulapac has the advantage of being certified industrially compostable by BPI and food contact compliant (EU & FDA). A similar pattern of studied biodegradability properties is not found in other materials marketed for 3D printing. Furthermore, Sulapac Flow has a beautiful natural look and feel providing the printed objects a unique finish and premium touch. Collaboration that adds value for our cosmetics customers Earlier this year we were pleased to announce our first collaboration in the field of 3D printing. GEHR, one of the leading producers of thermoplastic semi-finished products globally, introduced the first in the world 3D filament from sustainable Sulapac® material. We are particularly pleased with this cooperation, as GEHR is an established player with extensive know-how and experience in serving large cosmetics companies can provide significant added value to our cosmetics customers not only in 3D printing but potentially in other areas as well. Cosmetic brands can use the ECO-FIL-A-GEHR Wood filament for prototyping or creating sustainable point-of-sale structures, for example. The first commercial 3D printed product: loudspeaker with reused components Another collaboration we are very excited about is Sfaira, a 3D-printed loudspeaker by RD Physics. It is the first commercial 3D printed application made from Sulapac material, and as a product it’s ecological, chic, and quick to manufacture. RD Physics disassemble old loudspeakers, inspect and measure the components and use them in a new product. The enclosure of the Sfaira loudspeaker is made of bio-based and biodegradable Sulapac Flow 1.7 material. Their mono-material design principle allows easy recycling of the materials at end-of-life. “We got in touch with the company at a business event, and in only two months, we had the first loudspeaker ready”, says Mikko Huttunen, Manufacturing Development Lead at Sulapac. “This shows not only the agility of the collaboration between the two start-ups but also the undeniable speed of 3D printing”, Huttunen notes. “With injection molding technology, for example, even molds could not have been made in the same time”. 3D printing is perfect for pieces that don’t require large production quantities but have challenging shapes. RD Physics, for example, can make its loudspeakers in any shape, according to the customer’s wishes. Industrial-scale 3D printing straight from granules The Sfaira loudspeaker by RD Physics is printed with a filament made of Sulapac, which is still the most common way of 3D printing. Another form of 3D printing, directly from granules, is also possible with Sulapac materials. “We already have the proof of concept for this technique”, shares Huttunen. “Now we are exploring many different application possibilities for several of our materials.” Sulapac Flow 1.7 is indeed suitable for many applications and manufacturing technologies. Besides extrusion and 3D printing the material can also be used in thermoforming. The possibilities with Sulapac are endless. Start by exploring the world of 3D printing: sulapac.com/3d-printing-material You are also welcome to contact our sales for further information and insights: sulapac.com/contact/

* All content is copyrighted by Industry Intelligence, or the original respective author or source. You may not recirculate, redistrubte or publish the analysis and presentation included in the service without Industry Intelligence's prior written consent. Please review our terms of use.